Flixborough

revisited

NOTE: This webpage was first posted in January

2005 and, slightly abridged, appears in The Chemical Engineer

(April 2005). It has been modified for consistency with the

published version - save for Figure Nos. 7-10 that continue the

Figs 1-6 sequence of Flixborough

– Some Additional Lessons ("SAL")

and that two additional illustrations in the published version

appear in Flixborough

– FAQs.

In

June 1974, a 2-year-old caprolactam plant near Flixborough was

destroyed by a major explosion. Its shock waves echoed all around

Britain as neighbours of similar or older plants deluged

politicians with fears about nearby installations. Within days,

the government decided that a Public Inquiry was necessary to

allay public concern.

Fig. 7 Photograph of Section 25A at a late stage in its

construction

Its

outcome seemed a foregone conclusion. It was obvious that a

temporary by-pass line had jack-knifed and ripped away its

bellows connections to the 28" nozzles at both ends - and

never any doubt that the explosion was fuelled by a major escape

of superheated cyclohexane through these two open nozzles.

Officially

the Public Inquiry was asked to “establish the causes and

circumstances of the disaster.” However, as the

circumstances seemed unique, it was anticipated that the Court of

Inquiry would reassure the public that there was nothing to fear

from all other chemical plants. At that time (June 1974), there

was near-universal agreement that the 20" line was the sole

cause of the disaster (the so-called 20" line hypothesis).

Fig. 8 Court Plate 8 and a photograph of the 20" line

after explosion

To

demonstrate their hypothesis, the Court commissioned a replica 20"

line to be fabricated and connected by replica bellows between

two of the remaining reactors, to simulate what was thought to

have happened. It was announced, in advance of the opening of the

Public Inquiry, that the film of this simulation would be made

available publicly and would demonstrate what had caused the

explosion.

There

was, however, a dissenting voice. Dr. Keith Gugan, an experienced

accident investigator from Burgoynes, had found an 8" line

that, from its petal shaped fracture, he deduced had burst

through creep failure under pressure. He argued that this would

have occurred before the 20" line had jack-knifed (and

relieved the system pressure) and that that this pre-event must

have been the initiating cause of the disaster. In the jargon of

the Court, his event sequence became known as the 8" line

hypothesis.

When

the Court convened and heard eye-witness evidence from the

laboratory, it quickly became apparent that no-one had seen the

20" line fail (although it was visible from the laboratory)

and that all witnessed something other than the massive escape of

gas before the main explosion. Their accounts suggested that

there must have been one or more pre-events that activated the

fire siren at least 10 seconds before the jack-knife failure of

the 20" line and at least 30 seconds before the main

explosion.

Then,

a few days into the hearings, the Court conducted their

simulation test. As predicted, the 20" line did fail when

extra internal pressure was applied – but not in the way

expected. Instead of tearing away from the 28" nozzles, the

line merely distorted (‘squirmed’) with both bellows

connections left intact (Fig. 3a in "SAL"). Their

simulation, specifically designed to show that an over-pressurised

20" line initiated the train of events, actually showed that

an external force, applied from above, was needed to cause the

jack-knife. Scientific objectivity then went on hold as the Court

desperately tried to rescue its preferred hypothesis.

This

was not their only concern. By then it was known that something

unusual had happened in an overhead bank of fin-fan coolers.

Whilst most were crushed in situ when the plant structure

was felled by the main explosion, two rotors had flown upwards

and at right-angles to the main blast (Fig. 5A in "SAL"),

landed outside the structure (Fig. 7) and then were covered with

soot from the flash fire (that occurred concurrent with the main

explosion).

Fan

Rotor 8 (landed past roadway)

Fan Rotor 9 (landed on roadway)

Fig. 9 Fan rotors 8 and 9 after explosion, covered in soot

from flash fire

So,

two weeks into the public hearings, the Court’s single event

hypothesis faced a major challenge. It had to explain more than a

dozen eye-witness accounts of at least two events before the main

explosion – and, even more difficult, how creep failure in

the 8" line and an explosion in the fin-fan coolers could

have followed afterwards.

In

retrospect it is obvious that the proceedings should have been

adjourned to allow time for scientific tests to resolve the

technical issues. Unfortunately, the Court had already ‘gone

public’ in favour of its 20" line hypothesis. The Court

decided to hear evidence on various peripheral issues whilst it

conducted new investigations that, they hoped, would restore

scientific credibility to their preferred hypothesis.

Simultaneously,

various other issues of concern were under study – most of

which have been recorded in research reports and/or presented at

the IChemE symposium held at the end of 1975. The most relevant

of these for the causation issue concerned “zinc

embrittlement of stainless steel” – and were

conducted by Mr. Orbons of DSM.

His

findings explained why fin-fan coolers that were made from

stainless steel had shattered (whilst those from mild steel

remained intact) and revealed, inter alia, that the

explosion in the stainless steel fin-fan coolers (numbers 7-10)

could have been caused by a fire of only a few seconds. The Court

accepted that this caused the fin-fans’ explosion - but not

that it must have occurred before the main explosion.

Meanwhile,

the 8" line had remained in the care of the Court but (as

they did not think it relevant to causation) not available for

metallurgical examination. Eventually, just before the Christmas

recess, when the Court was satisfied it had the evidence it

needed to complete its findings, it was released for forensic

tests by Sir Alan Cottrell and Professor Peter Swann.

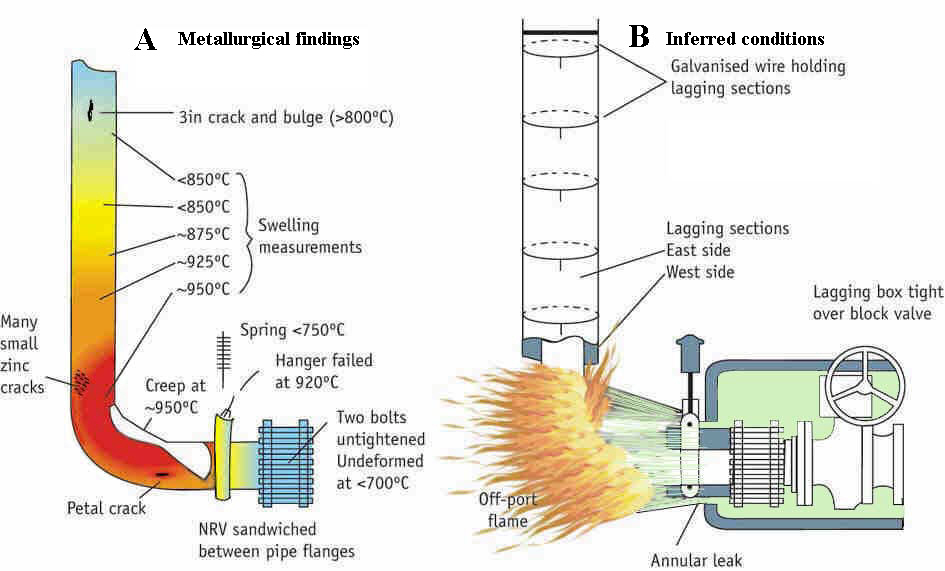

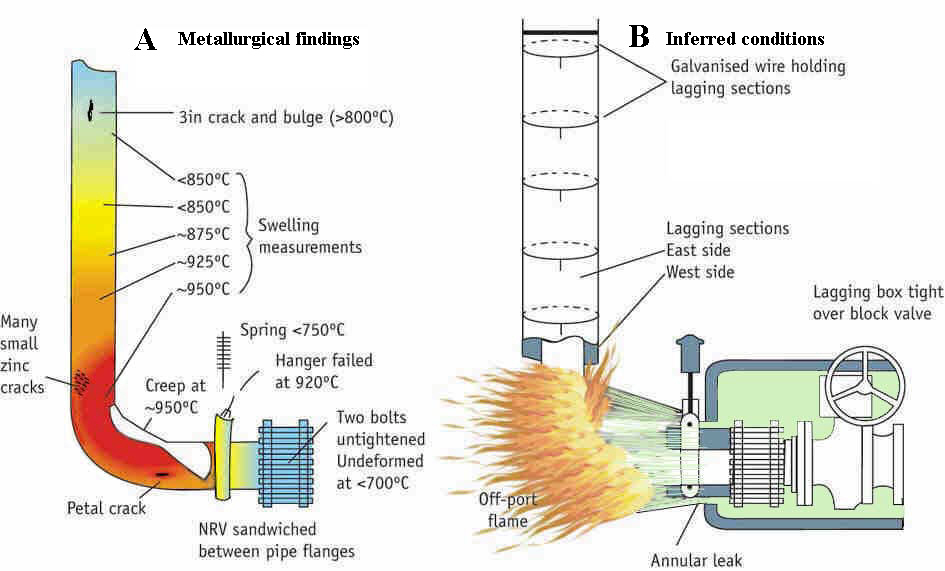

Their

creep rupture tests were conclusive. These showed that the

metallographic and morphological characteristics of the failure

of the 8" line at its elbow were consistent with failure

after about 4 minutes between 950°C and 1000°C at its normal

working pressure (equivalent to 7.4kg/mm2). This is

illustrated in Figure 10 (copied from The Chemical Engineer,

April 1976, page 270).

Fig. 10 Examples of w-type creep cavities in steel of 8”

line

Given

that tens of tonnes of cyclohexane would have escaped from the 28"

nozzles within 4 minutes of the 20" line jack knife (more

again from equipment damaged by the main explosion within a

minute of the first event), it is inconceivable the normal

working pressure would have been retained in the 8" line for

4 minutes if, as argued by the Court, the 20" line was first

to fail. Moreover, the direction of the applied stress was

consistent creep failure in an undistorted 8" line.

This was convincing evidence that the 8" line actually

failed before the 20" line.

Nor

was this all: Cottrell and Swann also determined the temperature

profile of nearby sections of the 8" line (Fig. 6A), showing

a rapid fall from 950°C at the intrados of the elbow to less

than 750°C only a few feet away. This confirmed that something

other than the general fire after the explosion must have been

responsible for highly-localised heating at the intrados (hypothesised

in Fig. 6B).

Figure 6 - reproduced from tce, May 1976

Lacking

further forensic evidence, the missing details of the hypothesis

then had to be completed by a sequence of credible conjectures:

ü

There was a gasket leak at the nearby non-return valve (a

credible scenario as two bolts were found to have been left

untightened).

ü

This leak resulted in an escape of cyclohexane that was directed

at the intrados of the elbow from an essentially intact lagging

box.

ü

The escape ignited and preferentially heated the sections of

lagging over the intrados and nearby.

ü

The lagging disintegrated and the zinc-coated wires (used to keep

the lagging in place) contacted (or came very close to) the

stainless steel pipe.

ü

The 3" crack (top of Fig. 6A) was created instantly by zinc

embrittlement.

ü

With cyclohexane now escaping on either side, the intrados of the

elbow became vapour-locked and its temperature rose to 950°C.

ü

After another 4 minutes, creep failure occurred at the petal

crack.

Having

conjectured this scientifically credible sequence of events that

conformed to the unimpeachable hard forensic evidence, the eye-witness

statements were reviewed (Figures 4 and 5A of "SAL").

Using the main explosion as the fixed time origin and working

back by re-enactments of what each witness remembered seeing,

hearing and doing just beforehand, it was easy to establish that:

ü

More than 20 eye-witnesses saw flames up to ¾ minute earlier.

ü

Of these, 8 described a vertical flame consistent with an

emission from the ruptured elbow of the 8" line up to 25

seconds earlier.

ü

One eye-witness (at location 15 of Fig. 4 ) reported seeing, at

least 25 seconds earlier, an object consistent with the

trajectory, shape and size of Fan Rotor 9 in flight.

ü

The 7 laboratory eye-witnesses (Fig. 5A) were alerted at least 32

seconds earlier and were running for safety within 10 seconds (without

having seen the 20" line collapse).

In

all, over forty eye-witnesses provided statements for scrutiny.

None contradicted the 8" line hypothesis: several

provided strong confirmatory evidence and helped to determine the

timing of events. From the standpoint of science, the debate

ended with the forensic metallurgical findings. If the sole

consideration for the Public Inquiry was to find the truth, it

would have endorsed this multi-event and multi-cause explanation.

But

there was a problem. The 20" line hypothesis did not

blame anyone outside Nypro and was preferred by the process

licensors and plant constructors, the Factory Inspectorate and

everyone already on public record in its favour. These were

pressing commercial, institutional and personal objections to the

8" line hypothesis. None of the parties represented

at the hearings would benefit if it were adopted.

Its

adoption would have obliged the Court to highlight a frightening

large number of defects in plant design and construction (loose

bolts, gasket integrity, vulnerability of stainless steel in

contact with zinc, the hugely damaging potential of a jet fire,

an excessive inventory of superheated cyclohexane). These would

have been unpalatable findings for a public looking to the Court

for reassurance.

So

the Court held firm. Their report reasserts (Para. 209) that the

20" line was the sole item at fault: “The disaster

was caused by the introduction into a well-designed and

constructed plant of a modification which destroyed its integrity”.

With the hindsight of maturity – though I did not think so

at the time – I concede that they may have had some excuse

for their technically implausible conclusion.

If

they had endorsed the more credible hypothesis, with all its

attendant lessons, it could have exacerbated fears about the

location of chemical plants. The Nypro plant was ½ mile from the

nearest village (Flixborough) yet 72 out of its 79 houses were

damaged. It was thought to be one of the most modern plants in Britain

at that time and built in accordance with the best practice of

the day. If two loose bolts initiated the Flixborough events, was

anyone safe living close to a chemical plant?

These,

I am sure, are the reasons why the Court reached its

scientifically perverse decision. They were impelled to blame the

totally unsuitable 20" line as a one-off cause of the

disaster - and give the rest of the Nypro plant (and, by

implication, all others in Britain) a clean bill of health. This

decision was predictable and signalled well in advance of their

Report.

Their

predicament had been explained to me, weeks before the hearings

ended, by the Secretary to the Inquiry, a senior Factory

Inspector of high personal integrity who had been present

throughout the proceedings. He advised me then to concentrate on

the lessons of the investigations and gave a pledge that the

Factory Inspectorate (then in transition to becoming the HSE)

would publicise all the lessons of Flixborough –

irrespective of the Court’s findings.

Bernard

O’Reilly kept his word and I took his advice. My main

efforts, after the official report was out, were to publicise the

lessons from the investigations. Within a few months the

Institution of Chemical Engineers had endorsed my personal

proposal that it sponsor a symposium on “The Technical

Lessons of Flixborough.”

It

was held on 16th December 1975 in Nottingham and its

papers published in the April/May 1976 issues of The Chemical

Engineer. My contribution, “Flixborough – Some Additional

Lessons”, reprinted for this website, created so much

interest that several hundred extra copies were reprinted as a tce

supplement. Although it focused on the lessons for the future and

was not meant as a backward-looking review of the causation

hypotheses, much of this interest stemmed from its implicit

explanation of (what tce termed) the “main

alternative theory to that put forward by the Court”.

Today,

thanks to the efforts of an indefatigable Ralph King and an

unwavering Jim Venart, it remains common knowledge that the Court

of Inquiry did not win universal approval. Thankfully, throughout

the past thirty years, safety professionals have ignored the

central conclusion of the Public Inquiry (Para. 209) and

concentrated on its ‘unofficial’ lessons. One example

will suffice: the concept of “Inherent Safety”.

This

supposed “well-designed” plant had 200 tonnes of

superheated cyclohexane circulating without a single ESD

isolation valve to reduce an escape. There was no way the plant

operators could contain a leak, irrespective of its cause or

location. Had the IChemE (and, notably, Trevor Kletz) accepted

the Court’s findings, the concept of “Inherent Safety”

– now an integral feature of design safety philosophy -

would not have seen the light of day.

For

further details, see the original “Flixborough – Some Additional

Lessons”.

John

Cox, January 2005