On 3rd

October 1996, a tanker containing a 25% solution of sodium

chlorite arrived at the Avonmouth works of Albright & Wilson

(A&W). After admission at the weighbridge it was checked by a

chemist and directed to the epichlorohydrin storage area.

On 3rd

October 1996, a tanker containing a 25% solution of sodium

chlorite arrived at the Avonmouth works of Albright & Wilson

(A&W). After admission at the weighbridge it was checked by a

chemist and directed to the epichlorohydrin storage area. On 3rd

October 1996, a tanker containing a 25% solution of sodium

chlorite arrived at the Avonmouth works of Albright & Wilson

(A&W). After admission at the weighbridge it was checked by a

chemist and directed to the epichlorohydrin storage area.

On 3rd

October 1996, a tanker containing a 25% solution of sodium

chlorite arrived at the Avonmouth works of Albright & Wilson

(A&W). After admission at the weighbridge it was checked by a

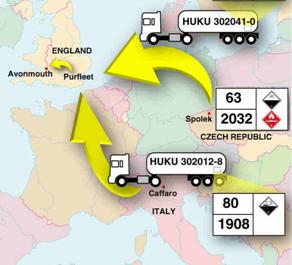

chemist and directed to the epichlorohydrin storage area. About the same time,

A&W had placed a blanket order for four consignments of epichlorohydrin

from Biachem Limited. Biachem sourced the material from

Spolek in the Czech republic and also engaged Huktra.

About the same time,

A&W had placed a blanket order for four consignments of epichlorohydrin

from Biachem Limited. Biachem sourced the material from

Spolek in the Czech republic and also engaged Huktra.criminal prosecution

Following the explosion, the Health & Safety Executive sought to prosecute A&W, Huktra and Biachem under the Health & Safety at Work Act. A&W and Huktra both pleaded guilty. His Honour Judge Bursell QC rejected the prosecution’s submission (against Biachem), accepting that Biachem were not responsible for the documentation error(2).

This was a significant judgement. It allayed fears from R v

Associated Octel Co Ltd(3) that companies had

become automatically liable for the actions of their sub-contractors.

It “showed a reluctance to take Octel further than was

intended by holding an employer responsible for the acts of

independent contractors regardless of the nature of those

activities”(4) (Claire McNamara, Hazardous

Substances, June 1999) - welcome news for those who feared that Octel

made companies responsible for events wholly outside their

control.

safety issues

The HSE, subsequently, has focused on what a receiver should do to prevent a similar occurrence. This accords with the views of safety professionals(5), as reported in tce in November and December 1996. The HSE identified the following as key lessons to be learned and examined when considering receipt of materials from road tankers:

· No preventative measures were in place to safeguard against the addition of a material, reactive with the substance in the storage tank (in this case epichlorohydrin).

· The documentation carried with the driver was not checked against the original quality documentation (e.g. for tank number) and the hazard markings on the tanker were not checked.

These highlight the fact that, in addition to forming part of quality and commercial systems, the procedures for identification of material delivered in road tankers and ensuring its unloading into the correct storage tank form part of a safety system which should be examined with the same degree of rigour as any other.

As stated during the HSE prosecution in 1999, “It is a matter of disbelief that the load got through.(7)” The tanker displayed a “corrosive” hazard symbol and the codes for chlorite solutions (ADR “80”, UN “1908”) – yet those on duty at the gatehouse, in the laboratory and at the plant, who (unlike the tanker driver) were familiar with both chlorite solutions and epichlorohydrin were not required to and did not check whether these were consistent with an epichlorohydrin delivery.

Also, having recently discontinued sampling and analysis, the residual quality control procedures did not require the incoming tanker number to match the number on the Certificate of Analysis! Any of these checks would have alerted A&W to Huktra’s documentation error and could have prevented the explosion.

Immediately after the event, A&W instituted measures to check tank numbers, labels and placards – exactly as had been suggested by the Laboratory Superintendent after an incident in 1989. Given that the ALARP principle dictates that all “reasonable and practicable” measures that reduce risk should be implemented, it is clear that A&W share some “blame” for the explosion.

A&W and Huktra were found guilty of offences under the Health and Safety at Work Act, and fined £60,000 ($110,000) and £15,000 respectively. The cost of the damage to the Avonmouth Plant exceeded £10million.

civil prosecution

HSE’s focus on the shortcomings of the raw materials acceptance procedures contrasts with the prosecution subsequently pursued by A&W (actually Rhodia – who by then had acquired the Avonmouth site). The civil claim relied on the contractual failing of Berk(!) to deliver the right documentation with the sodium chlorite solution. As Berk had no direct control over the actions of Huktra or Stevens, this claim revives the spectre of Octel and could have far-reaching implications for industry.

Why the civil claim ignored “blame” (in the sense of “what might have been done to prevent the incident”), is explained in a preliminary judgement of Lord Nicholls(8) in the House of Lords:

“Had Albright & Wilson advanced claims in negligence ... no doubt it would have been met with a plea that Albright & Wilson was itself guilty of contributory negligence when its employees at Avonmouth directed the tanker containing sodium chlorite to the tanks where the epichlorohydrin was stored. In order to avoid any such plea of contributory negligence being raised Albright & Wilson has advanced its claims ... solely on the basis of loss arising from breach of contract. It has eschewed a claim based on a failure to exercise care, either in tort or contract”.

For the civil claim, the House of Lords ruled that the contract between Berk (the suppliers of sodium chlorite) and A&W was being executed - making Berk the target defendant. In response, Berk argued that A&W had not fulfilled a contractual obligation to discharge their consignment to the correct storage vessel.

natural justice

"Natural

justice" (as opposed to the law of contract) requires that

"the punishment must fit the crime." It is not clear

what crime Berk committed. Their contractual arrangements

with A&W were undermined by the actions of parties over which

they had effectively no control: it was not they who had

introduced a delivery  note for another

company which became associated with their load. It is

ironic that the same events that seemed to limit the

applicability of Octel (through the failure of the HSE to

secure prosecution against Biachem) has raised an even greater

concern - that companies could be held liable for the actions of

others with whom they have only the most tenuous contractual

relationships.

note for another

company which became associated with their load. It is

ironic that the same events that seemed to limit the

applicability of Octel (through the failure of the HSE to

secure prosecution against Biachem) has raised an even greater

concern - that companies could be held liable for the actions of

others with whom they have only the most tenuous contractual

relationships.

A&W eventually agreed a settlement (details of which remain confidential) but, by instigating their civil claim, revived the spectre of Octel and diverted attention away from the lessons of the HSE prosecution.

What the chemical industry needs to do is concentrate on the implementation of the lessons learned – as published in the Chemical Industry Associations "Procedures for offloading products into bulk storage at plants and terminals” ISBN 1-85897-087-3 - to prevent the recurrence of similar incidents. As in most walks of life, prevention is better than the legal remedy. Moreover, in an ideal world, a party found guilty of negligence by a Health & Safety prosecution would be debarred from claiming against innocent parties – and the huge sums of money spent on legal technicalities would not have been wasted.

References

tce october 2004